Turnkey Rebuilt Hydromats

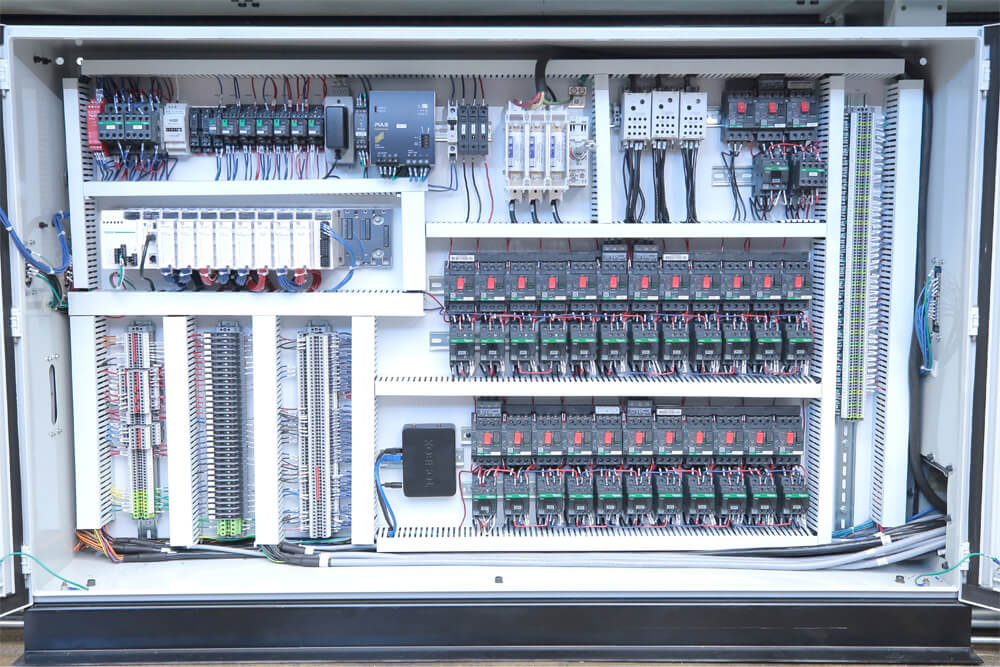

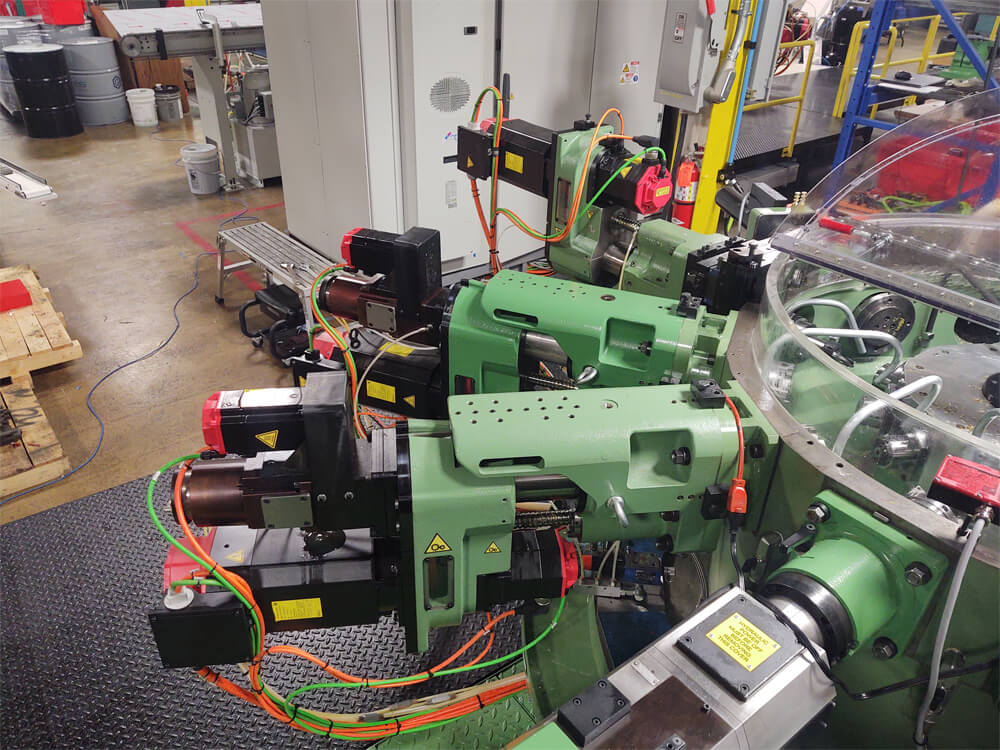

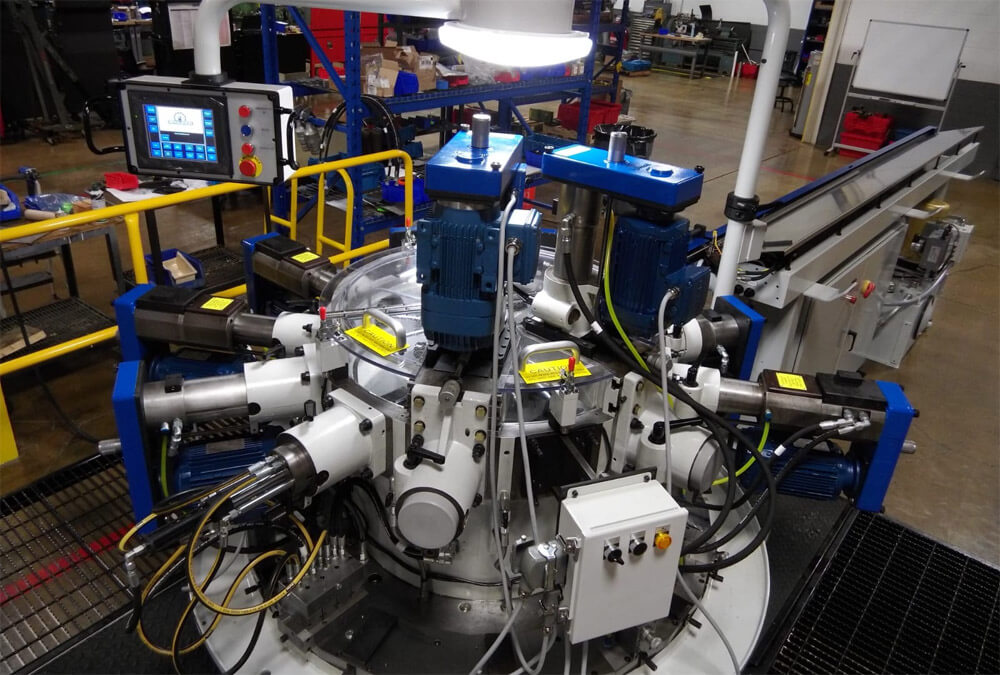

RMW is a full Hydromat rotary transfer machine rebuild, service, parts, training and used equipment company. Our team of experts can help you increase efficiency with a turnkey rebuilt Hydromat.

Versatility & Flexibility

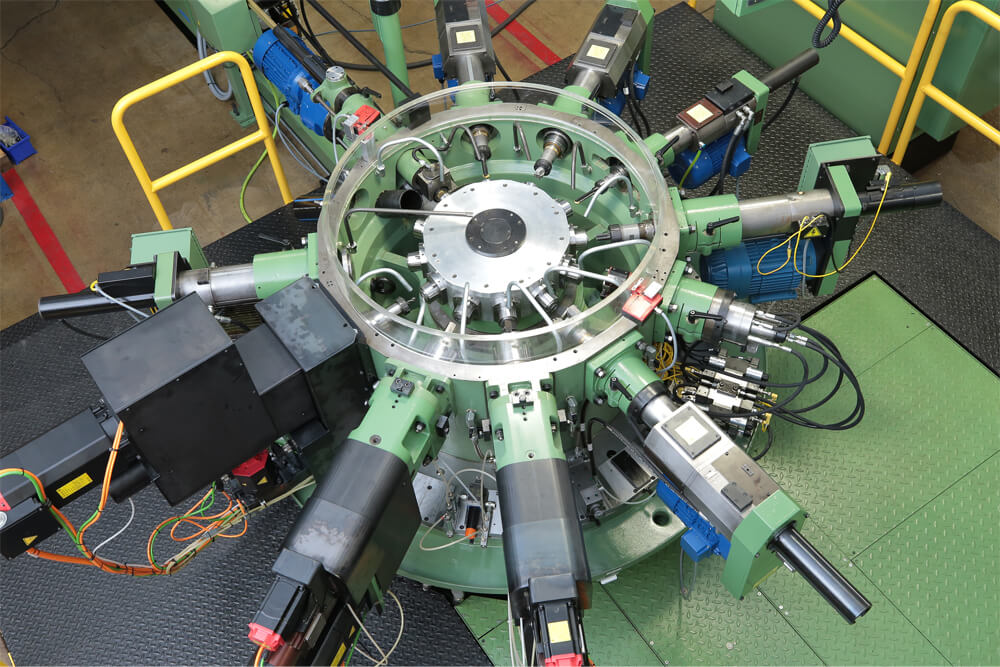

Turnkey rebuilt Hydromat rotary transfer machines are modular systems consisting of up to 16 horizontal and eight vertical tool spindle units rigidly mounted around a precision cast-iron base. This layout affords the capability of providing tremendous versatility and flexibility in a turnkey machining solution. With a 1.75" capacity, the machines are ideally suited to produce parts from bar stock or blanks up to 6" in length.

Cost-Effective Precision

Our turnkey rebuilt Hydromats offer consistent high production and precise machining, as well as the elimination of costly secondary operations — making them an outstanding solution for cost-effective manufacturing.

Machine Benefits & Features

Accuracy & Reliability of a Hirth Ring

Several Unit Sizes Available

Multiple Loading & Chip System Options

Significant Material Savings

Increased Productivity

Quiet, Vibration-Free Operation

Precision Table Indexing & Repeatability

Coolant & Chips Contained in the Tooling Area

Adaptable for Vertical Machining Requirements

Machine Specs

| Round |

|---|

| 1" |

| Hex |

|---|

| 7/8" |

| Square |

|---|

| 3/4" |

| Part Length |

|---|

| 4" |

| Horizontal Stations |

|---|

| 12 |

| Vertical Stations |

|---|

| 6 |

| Index Time |

|---|

| 0.500 sec |

| Weight LBS |

|---|

| 10,000 |

| Machine Power |

|---|

| 30HP (Avg) |

| Typical Unit Size |

|---|

| 20 Series |

| 30 Series |

| DM2 40/90 CNC |

| Round |

|---|

| 1 3/4" |

| Hex |

|---|

| 1 1/2" |

| Square |

|---|

| 1 1/4" |

| Part Length |

|---|

| 6" |

| Horizontal Stations |

|---|

| 12 |

| Vertical Stations |

|---|

| 6 |

| Index Time |

|---|

| 0.700 sec |

| Weight LBS |

|---|

| 15,000 |

| Machine Power |

|---|

| 43HP (Avg) |

| Typical Unit Size |

|---|

| 20 Series |

| 30 Series |

| 40 Series |

| 50 Series |

| DM2 40/90 CNC |

| DM2 55/120 CNC |

| DM2 55/200 CNC |

| Round |

|---|

| 1 3/4" |

| Hex |

|---|

| 1 1/2" |

| Square |

|---|

| 1 1/4" |

| Part Length |

|---|

| 6" |

| Horizontal Stations |

|---|

| 16 |

| Vertical Stations |

|---|

| 8 |

| Index Time |

|---|

| 0.8 sec |

| Weight LBS |

|---|

| 16,500 |

| Machine Power |

|---|

| 60HP (Avg) |

| Typical Unit Size |

|---|

| 20 Series |

| 30 Series |

| 40 Series |

| 50 Series |

| DM2 40/90 CNC |

| DM2 55/120 CNC |

| DM2 55/200 CNC |

| Blank |

|---|

| 4" Cube |

| Round |

|---|

| 1 3/4" |

| Part Length |

|---|

| 8" |

| Horizontal Stations |

|---|

| 12 |

| Vertical Stations |

|---|

| 6 |

| Index Time |

|---|

| 1.2 sec. |

| Weight LBS |

|---|

| 18,500 |

| Typical Unit Size |

|---|

| 20 Series |

| 30 Series |

| 40 Series |

| 50 Series |

| DM2 40/90 CNC |

| DM2 55/120 CNC |

| DM2 55/200 CNC |

| Blank |

|---|

| 3" Cube |

| Round |

|---|

| 1 3/4" |

| Part Length |

|---|

| 8" |

| Horizontal Stations |

|---|

| 16 |

| Vertical Stations |

|---|

| 8 |

| Index Time |

|---|

| 1.0 sec. |

| Weight LBS |

|---|

| 20,000 |

| Typical Unit Size |

|---|

| 20 Series |

| 30 Series |

| 40 Series |

| 50 Series |

| DM2 40/90 CNC |

| DM2 55/120 CNC |

| DM2 55/200 CNC |

| Round |

|---|

| 1.75" |

| Hex |

|---|

| 1.5" |

| Square |

|---|

| 1.25" |

| Part Length |

|---|

| .5" - 12" |

| Horizontal Stations |

|---|

| 12 |

| Vertical Stations |

|---|

| 6 |

| Index Time |

|---|

| .9 sec. |

| Weight LBS |

|---|

| 16,500 |

| Typical Unit Size |

|---|

| 20 Series |

| 30 Series |

| 40 Series |

| 50 Series |

| DM2 40/90 CNC |

| DM2 55/120 CNC |

| DM2 55/200 CNC |

| Round |

|---|

| 1.75" |

| Hex |

|---|

| 1.5" |

| Square |

|---|

| 1.25" |

| Part Length |

|---|

| .5" - 12" |

| Horizontal Stations |

|---|

| 18 |

| Vertical Stations |

|---|

| 8 |

| Index Time |

|---|

| .9 sec. |

| Weight LBS |

|---|

| 16,500 |

| Typical Unit Size |

|---|

| 20 Series |

| 30 Series |

| 40 Series |

| 50 Series |

| DM2 40/90 CNC |

| DM2 55/120 CNC |

| DM2 55/200 CNC |

Have Questions? Reach Out.

Speed of service, cost savings, parts availability and state-of-the-art equipment set us apart from the competition.

How Our Turnkey Rebuilt Hydromats Have Helped Clients

Save up to 70% on buying a rebuilt machine vs. new

Our rebuilds put the machines back to new OEM specifications. Why pay more for the same result? Save up to 70% buying rebuilt vs. new.

Part cycle times on rotary transfer machines can be up to 900% vs. traditional CNC lathes and mills

With up to 24 machining stations that can perform almost all types of machining, part cycle times can be reduced from minutes to seconds on Hydromat rotary transfer machines vs. traditional CNC lathes and mills.

25% increased production efficiency

With each station having independent speed/feed, automatic barload/cutoff and quick change tooling, Hydromat transfer machines can achieve up to 25% more part production vs. screw machines.

What Our Customers Say

“I believe in the team concept. We will do more and have a better product if we work together. RMW, from what I see, has that same vision.”

Matthew Bremiller, Engineering Supervisor

Dapco Industries

"Working with RMW says that I want to get things done the right way."

Steve Danielson, Manufacturing Engineer

Parker Hannifin

“Just like my business, RMW has the desire to solve problems quickly and effectively.”

Brian Thompson, Engineering Supervisor

Swagelok

"RMW excels at providing straightforward answers and accurate information."

Tom Kilpatrick, Senior Process Engineer

Alco

"RMW wants you and your company to succeed!”

John Riley, Process Engineer

Whitesell Precision Components