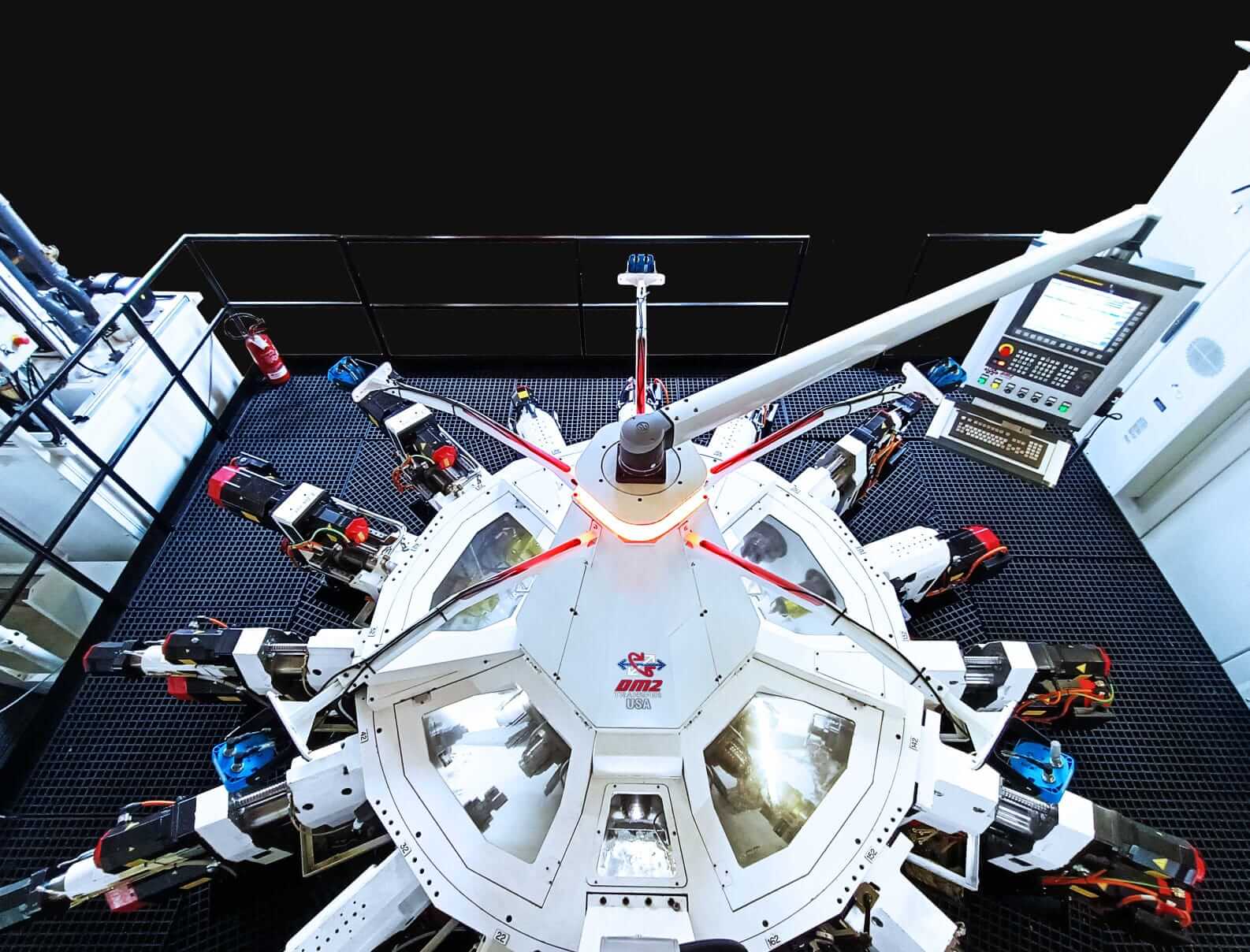

DM2 Technomats

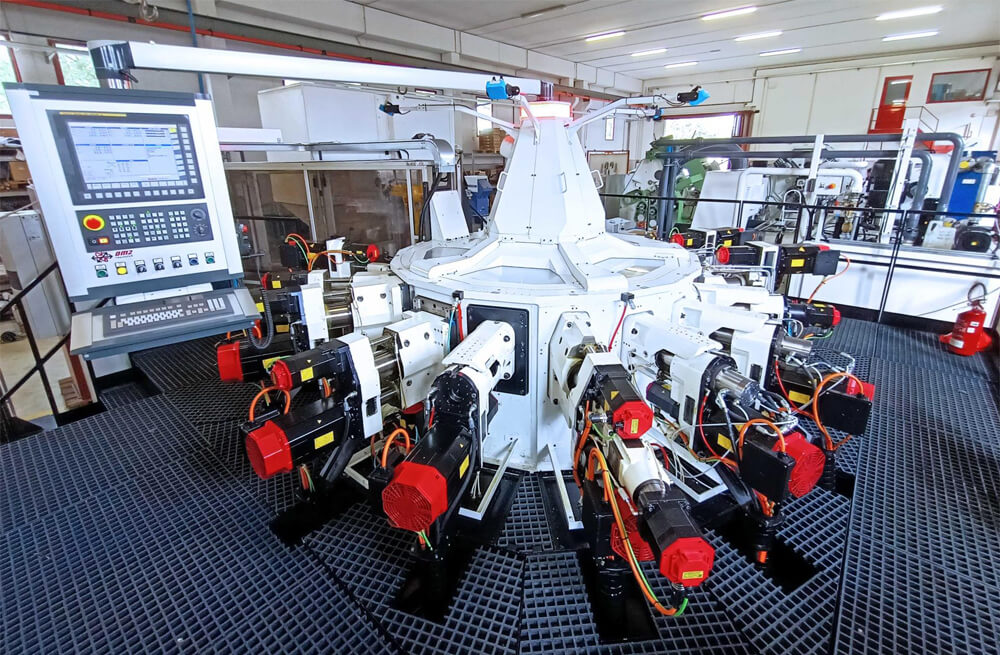

Our fully customized DM2 Technomat CNC machines, imported from DM2 transfer in Italy, offer increased part capacities up to 300 mm and ability to be equipped up to 16 stations and 24 machining units total. The hirth ring servo indexing table can be equipped with quick-change collets, rotating collets and 2 jaw chucks. This unmatched power and flexibility leads to reduced cycle times and the ability to perform all types of machining in a variety of materials and configurations.

Rigid, Accurate, Flexible Machine Bases

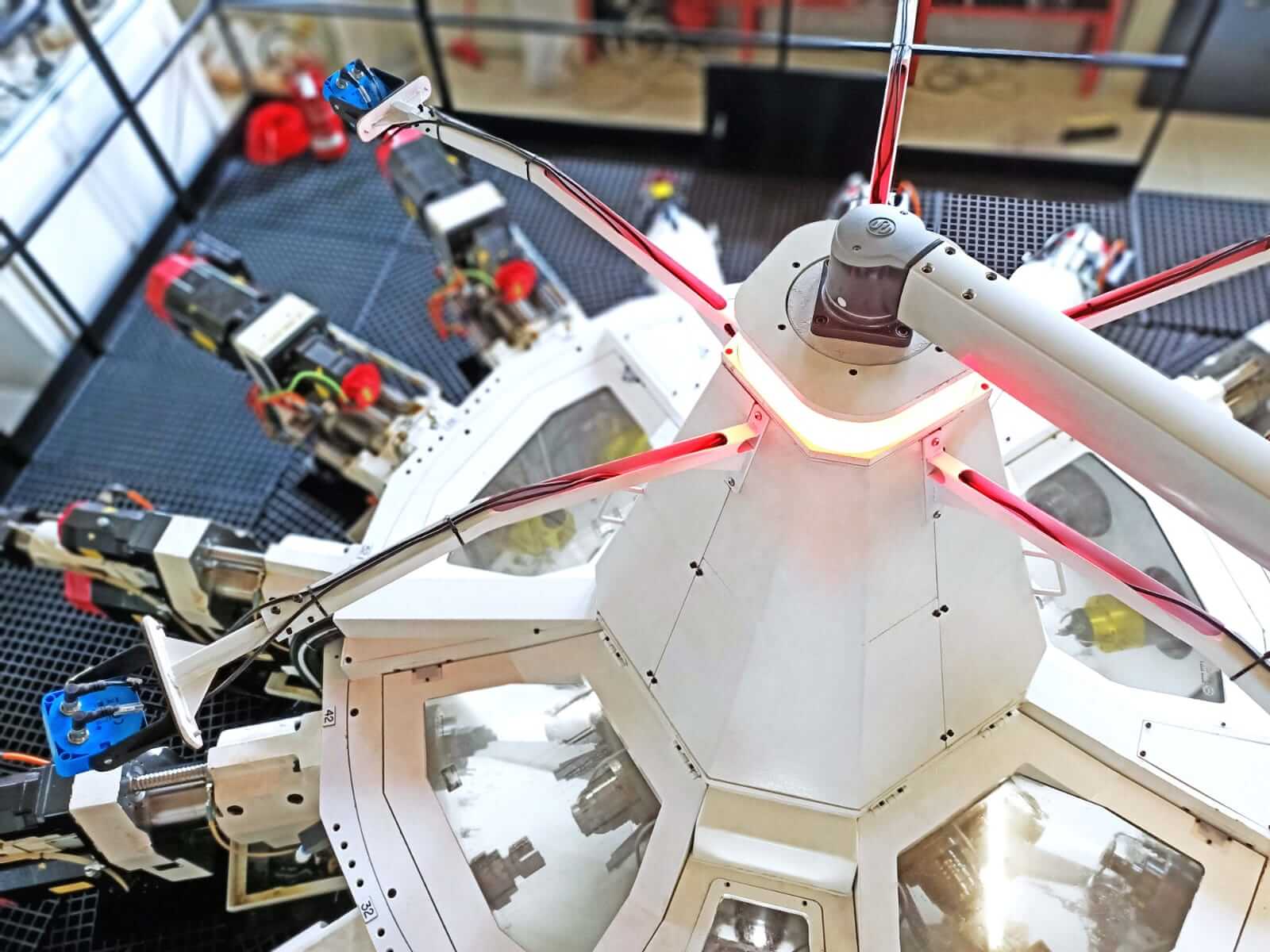

The first thing you will notice about the DM2 Technomats is how rigid their bases are. These machines are built to last. Meticulously constructed using traditional European machine tool building techniques at DM2 Transfer in Brescia, Italy, these cast iron and stress-relieved machine bases offers unparalleled accuracy, rigidity, and space, for multiple parts on the same machine. The hirth ring servo indexing tables index at 0.8 seconds within .0002” accuracy holding up to 2.0 cpk. With the DM2 Technomat machines coming in 3 different configurations the Technomat 100-16, the Technomat Trunnion, and the Techno Flex, we have the machine configuration and work envelope your mid to high volume machine projects require. Pairing this with RMW’s U.S.-based parts and service, our machines are the most heavy-duty and cost-effective in the industry.

Fanuc-Controlled DM2 CNC Units

The Technomat uses modular, Fanuc-controlled ballscrew CNC units to get the job done. DM2 Transfer has been using ballscrew CNC technology since the late 1990s and builds each unit to world-class tolerance standards to ensure quality and accuracy are there when you need them. With 1-5 axis machining units available up to 80mm spindle diameter and 200mm stroke, almost all machining operations can be completed with the power and precision your most challenging projects demand. Typical operations completed are turning, reaming, drilling, milling, slotting, knurling, cross drilling, multiple hole drills, deep hole drills, broaching, tapping, chasing, thread milling, single point threading, polygon turning and many more.

Find your custom solution among these three DM2 Technomat rotary transfer CNC machine models:

The Technomat 100-16

Open top, modular design. The Technomat 100-16 is a 16-station machine made up of a vertical axis indexing table with up to 16 horizontal units and 8 vertical units. Barfeeder or Robot load available. Collet, rotating collet and 2 and 3 jaw chuck table up to 100mm part capacity are available.

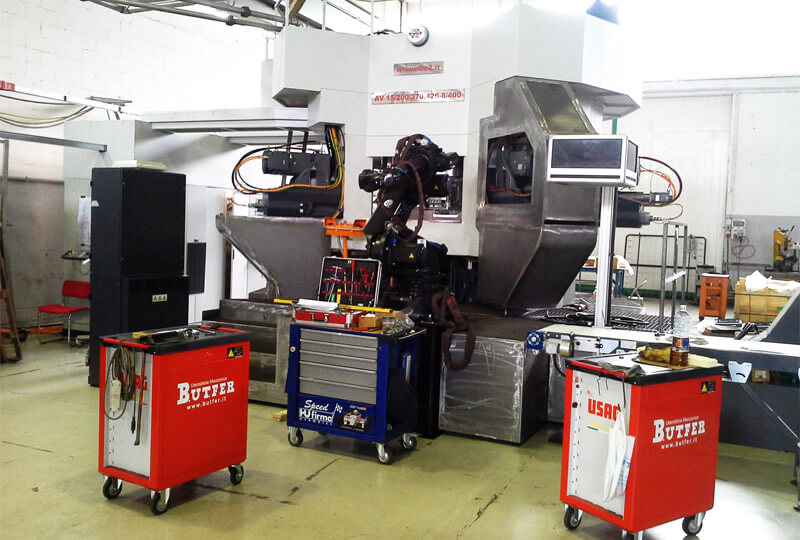

The Techno Flex (AV)

Great for machining Ts, 45 degree elbows, straights and many more types of parts. It consists of a vertical axis table with up to 12 stations, is fully loaded up to 33 CNC units and has the ability to machine from three sides simultaneously. This platform offers up to 4-axis rotating chucks and quick-change collets. Quick and flexible, designed for small production batches and with reduced tooling times thanks to four automatic tool changers on the machine. Able to work with various types of materials and products with part capacities up to 300mm.

Technomat Trunnion

is a compact and versatile configuration that has 12 stations and a horizontal axis indexing table with 12 x 2 jaw chucks for single production and 24 x 2 jaw chucks for double production. Suitable for machining parts in the automotive, plumbing and hydraulic sectors, this machine configuration allows for three-sided simultaneous machining with up to 33 CNC units and can produce parts out of bar or robot-loaded blanks up to 50mm capacity.

DM2 Technomat Benefits & Features

Rigid, built to last base with up to 16 machining stations and up to 300mm work-holding capacity

Three different machine configurations available

Index table equipped with hirth ring coupling with indexing accuracy within .0002”

Table index time: 0.8 seconds

Quick-change collets, rotating collets, 2 and 3 jaw chuck all available

1-5 axis ballscrew units

Drilling, tapping, threading, milling & deburring and much more

Bar feeders & cutoff units or robot loading with vision

HSK quick-change tool heads

Automatic tool changers

Tool monitoring/control

Fanuc 30i control with HMI pendant

Machine Specs

MACHINE CAPACITY (Without Modification)

| Round |

|---|

| 100mm |

| Hex |

|---|

| 95mm |

| Square |

|---|

| 90mm |

| Part Length |

|---|

| 200mm |

| Horizontal Stations |

|---|

| 16 |

| Vertical Stations |

|---|

| 8 |

| Index Time |

|---|

| 0.9 sec |

| Weight |

|---|

| 20,000 |

| Typical Unit Size |

|---|

| DM2 40/90 CNC |

| DM2 55/120 CNC |

| DM2 55/200 CNC |

MACHINE CAPACITY (Without Modification)

| WORKING ENVELOPE |

|---|

| 300mm |

| PART LENGTH |

|---|

| 200mm |

| HORIZONTAL STATIONS |

|---|

| 12 |

| VERTICAL STATIONS |

|---|

| 12 from top, 12 from bottom |

| INDEX TIME |

|---|

| 0.9 sec |

| WEIGHT LBS |

|---|

| 20,000 |

| TYPICAL UNIT SIZE |

|---|

| DM2 40/90 CNC |

| DM2 55/120 CNC |

| DM2 55/200 CNC |

MACHINE CAPACITY (Without Modification)

| WORKING ENVELOPE |

|---|

| 150mm x 100mm x 125mm |

| PART LENGTH |

|---|

| 300mm |

| HORIZONTAL STATIONS |

|---|

| Up to 28, 14 each side |

| VERTICAL STATIONS |

|---|

| Up to 14 |

| INDEX TIME |

|---|

| 0.9 sec |

| WEIGHT LBS |

|---|

| 20,000 |

| TYPICAL UNIT SIZE |

|---|

| DM2 40/90 CNC |

| DM2 55/120 CNC |

| DM2 55/200 CNC |

Have Questions? Reach Out.

Speed of service, cost savings, parts availability and state-of-the-art equipment set us apart from the competition.

How Our DM2 Solutions Have Helped Clients

Machine Part Sizes up to 300 MM

Machine part sizes up to 300mm with the same speed and precision as smaller parts due to three unique Technomat platforms.

Run up to 8 hours unattended “lights out”

With up to four automatic tool changers, Fanuc tool control/load monitors and advanced automation with vision, you can run Technomats for up to 8 hours unattended, lights out.

DM2 machines are installed in over 31 countries around the world

Since 1985, DM2 has strived to deliver the most powerful, accurate and technologically advanced rotary transfer machines in the world.

What Our Customers Say

“I believe in the team concept. We will do more and have a better product if we work together. RMW, from what I see, has that same vision.”

Matthew Bremiller, Engineering Supervisor

Dapco Industries

"Working with RMW says that I want to get things done the right way."

Steve Danielson, Manufacturing Engineer

Parker Hannifin

“Just like my business, RMW has the desire to solve problems quickly and effectively.”

Brian Thompson, Engineering Supervisor

Swagelok

"RMW excels at providing straightforward answers and accurate information."

Tom Kilpatrick, Senior Process Engineer

Alco

"RMW wants you and your company to succeed!”

John Riley, Process Engineer

Whitesell Precision Components