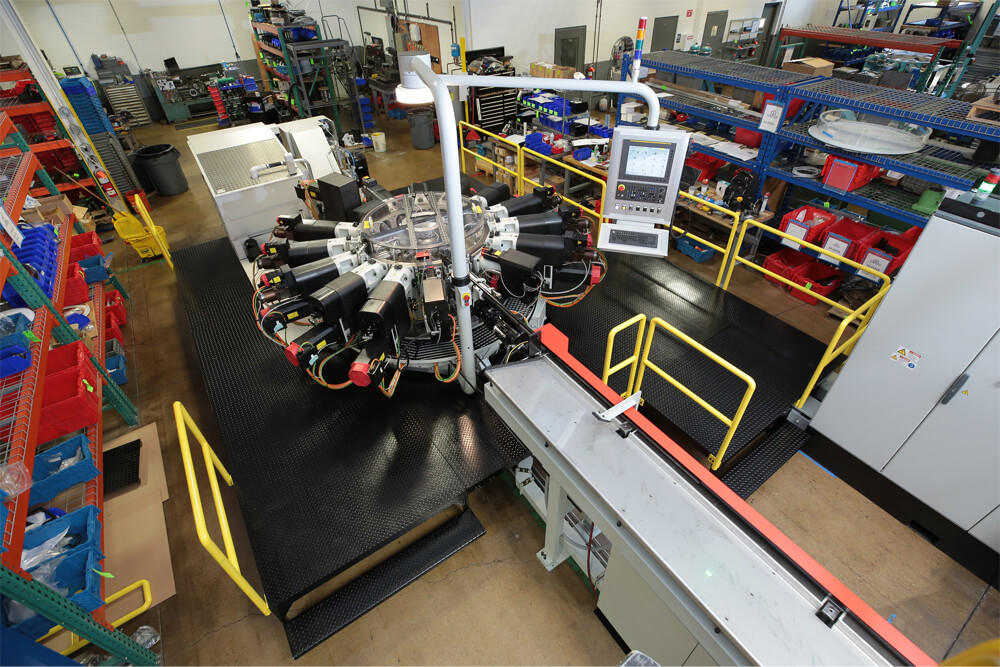

Servomat CNC Rotary Transfer Machines

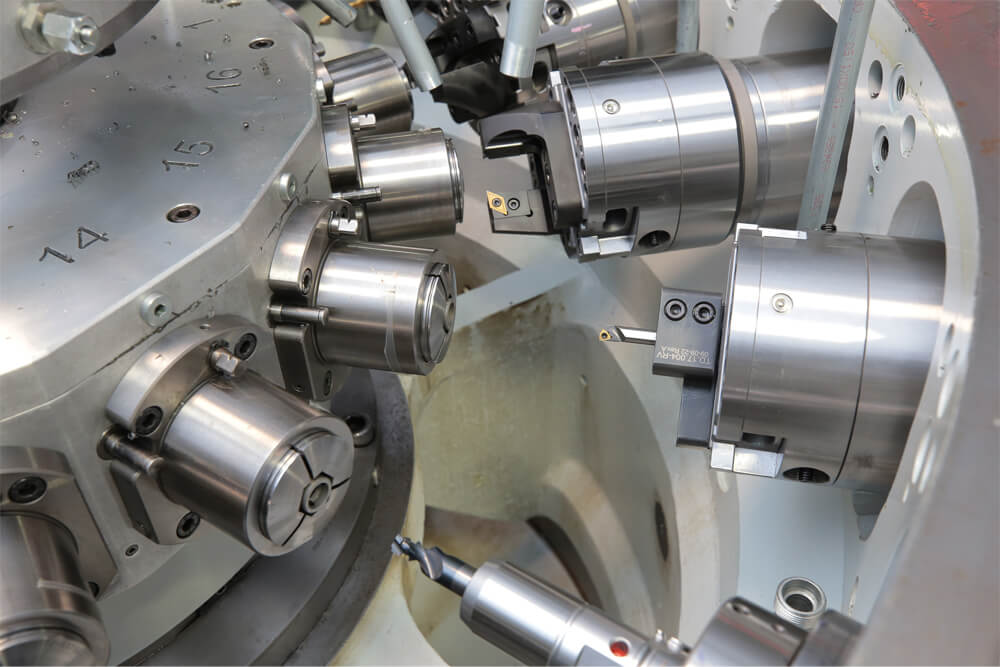

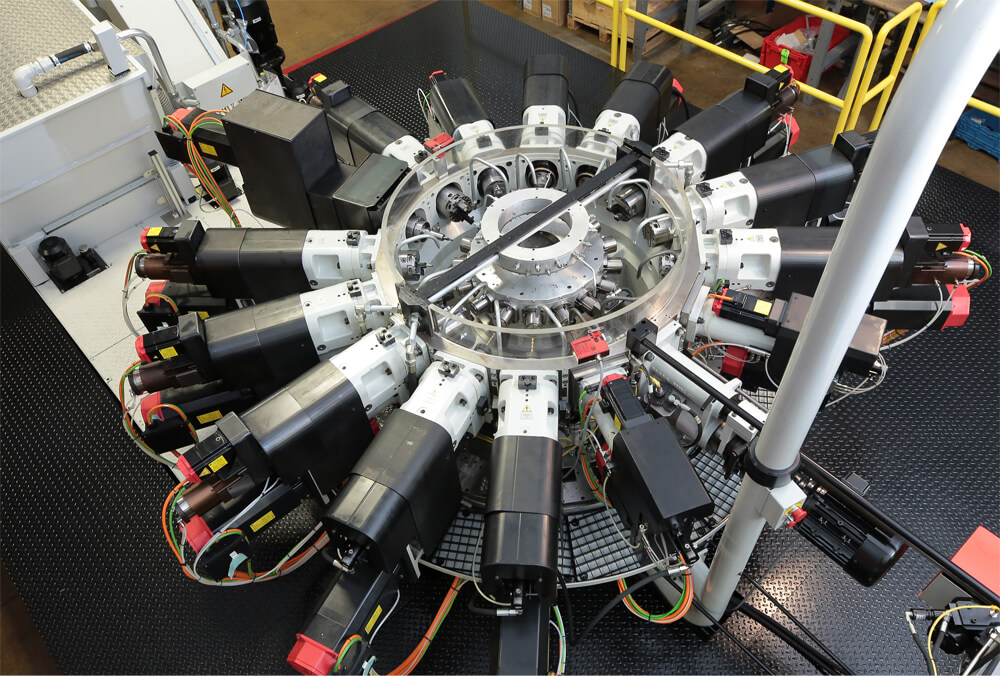

RMW pioneered the concept of upgrading Hydromat-type rotary transfer machines with ballscrew units by being the first company to introduce them to the US market in 2017. In 2022 we introduced the Servomat machine to our USA customers. A rebuilt Hydromat base with an all new knoll chip conveyor, bar feeder, platform, and fully equipped with DM2 Fanuc controlled ballscrew units, it was the first of its kind! Our customers have seen a 35% reduction in cycle times vs traditional hydraulic CNC units and it has allowed them to finally gain the uptime, power, flexibility, and precision that they needed to compete in today’s global market.

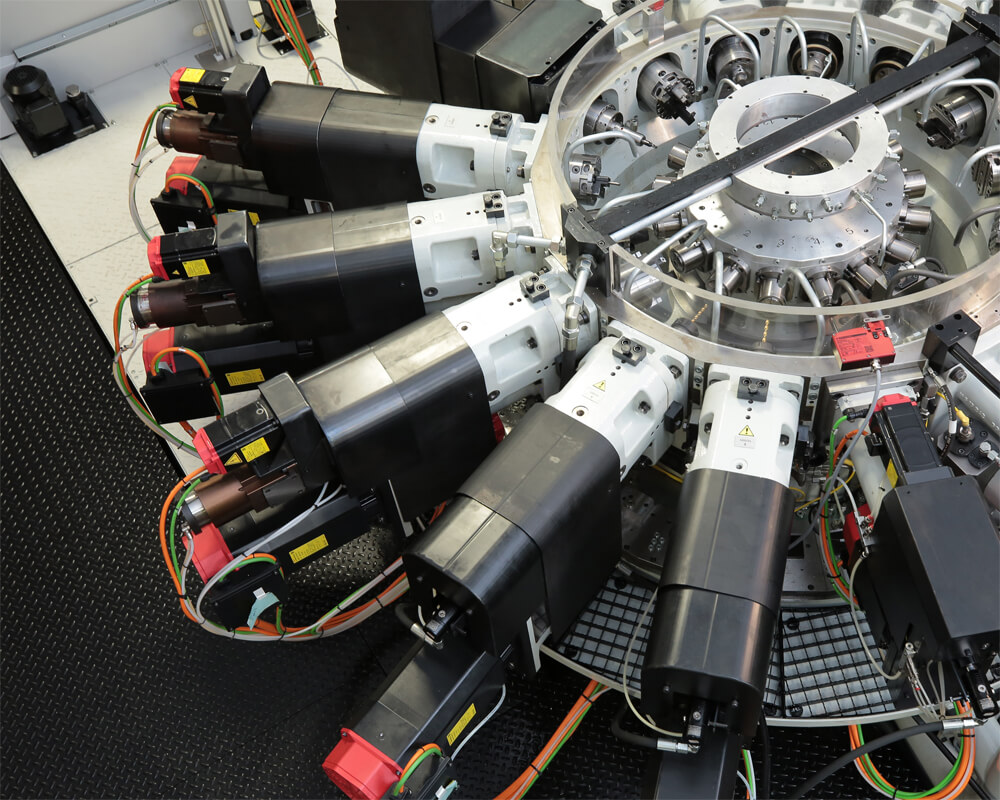

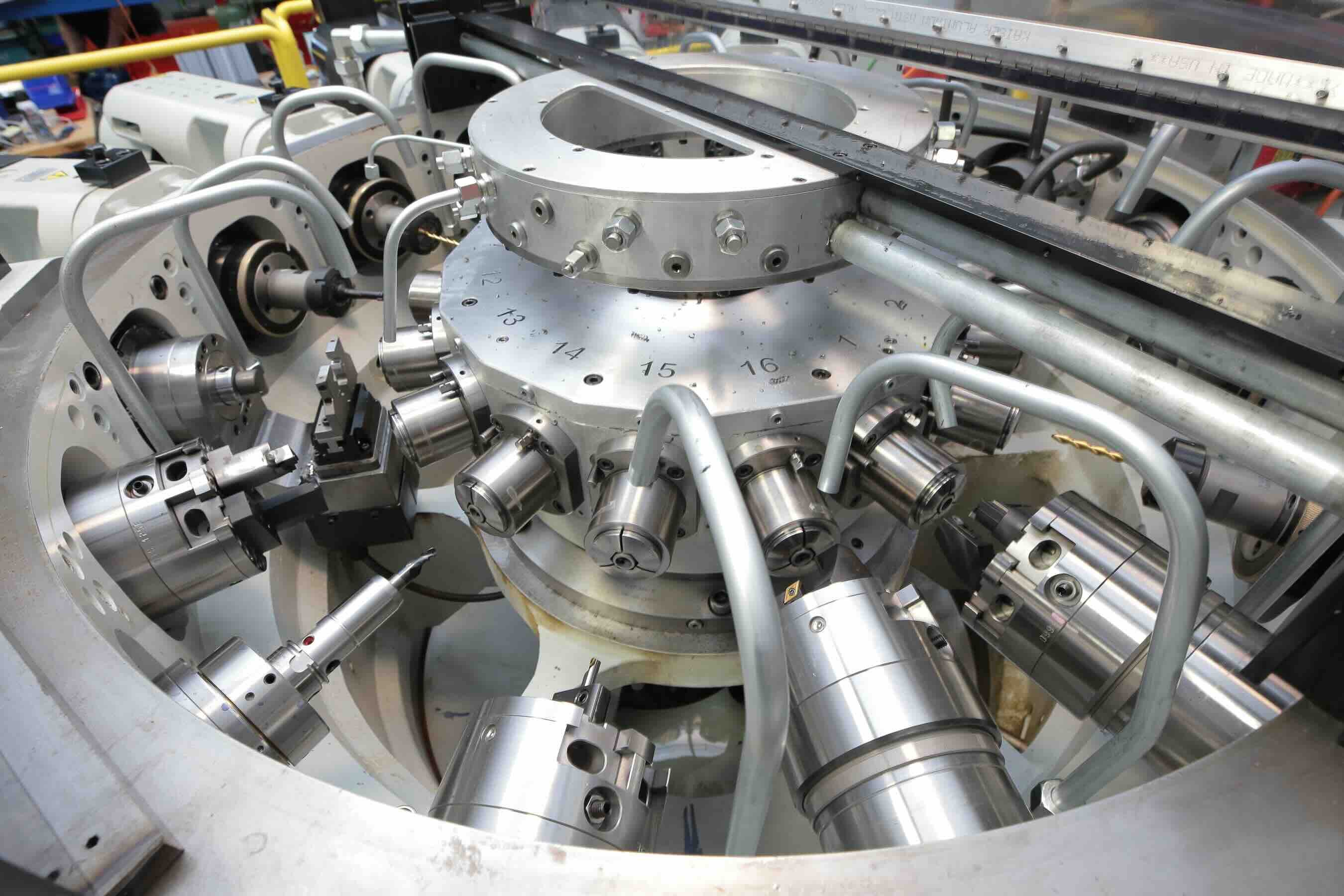

Hydromat Machine Base

For world-class accuracy and performance, it all starts with the base. To create our Servomat CNC rotary transfer machines, RMW rebuilds all legacy Hydromat base components using OEM specifications and practices. We strip the casting all the way down to bare iron and build it back up by replacing every bearing, seal and hydraulic fitting/line and updating electrical components to provide a reliable, accurate machine base.

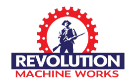

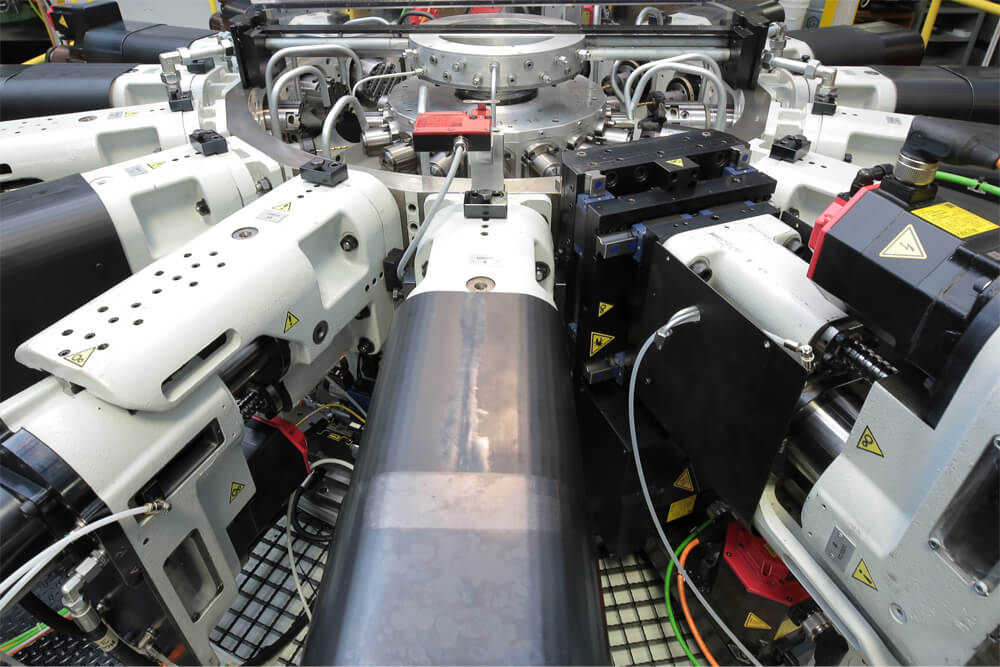

DM2 Fanuc-Controlled CNC Units

For unparalleled reliability and flexibility, it is all about units and control. The Servomat machine utilizes the extreme precision and rigidity of DM2 transfer’s modular CNC ballscrew machining units. These units have been in operation in Europe for over 30 years and we are the first company to introduce them to the North American market. We offer up to 5-axis milling and turning units, each with a modular design that can be moved easily in case a re-tool is necessary. The units are Fanuc-controlled so your controls will never become obsolete and you will always be supported with replacement components in stock at our headquarters in Cleveland, Ohio.

Machine Benefits & Features

High-accuracy rigid design

Up to 16 horizontal & 8 vertical machining stations

1-5 axis capable units

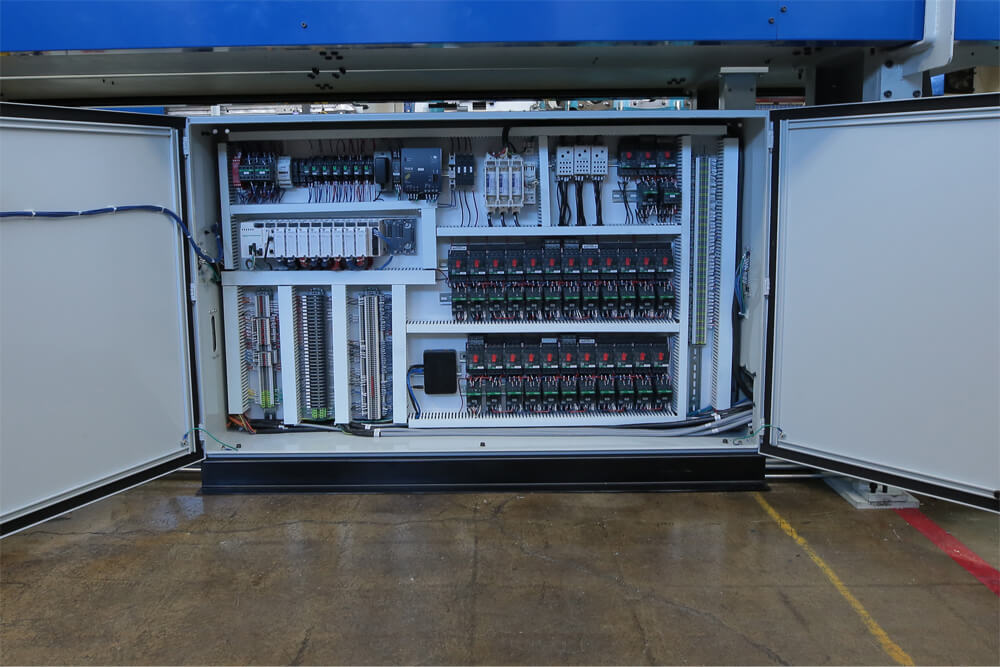

FANUC 30iB CNC control and touch screen HMI

Current Hydromat collets, ejectors, durable tooling and toolheads can be used

Hirth ring indexing collet table for world-class accuracy

Collet, 2, 3 jaw chuck, ID mandrel and indexing chuck tables available

Modular, Fanuc-controlled DM2 ballscrew units with HSK heads for easy changeovers

Bundle and magazine barfeeder allow for seamless and fast bar change

Ability to invert the part 180 degrees to machine both ends and eliminate secondary operations

Enclosed machining area for safety and cleanliness

No PMAC boxes

Units currently in production in the U.S. and full service and parts support available

Machine Specs

| Round |

|---|

| 1" |

| Hex |

|---|

| 7/8" |

| Square |

|---|

| 3/4" |

| Part Length |

|---|

| 4" |

| Horizontal Stations |

|---|

| 12 |

| Vertical Stations |

|---|

| 6 |

| Index Time |

|---|

| 0.500 sec |

| Weight LBS |

|---|

| 10,000 |

| Machine Power |

|---|

| 30HP (Avg) |

| Typical Unit Size |

|---|

| DM2 40/90 CNC |

| Round |

|---|

| 1 3/4" |

| Hex |

|---|

| 1 1/2" |

| Square |

|---|

| 1 1/4" |

| Part Length |

|---|

| 6" |

| Horizontal Stations |

|---|

| 12 |

| Vertical Stations |

|---|

| 6 |

| Index Time |

|---|

| 0.700 sec |

| Weight LBS |

|---|

| 15,000 |

| Machine Power |

|---|

| 43HP (Avg) |

| Typical Unit Size |

|---|

| DM2 40/90 CNC |

| DM2 55/120 CNC |

| DM2 55/200 CNC |

| Round |

|---|

| 1 3/4" |

| Hex |

|---|

| 1 1/2" |

| Square |

|---|

| 1 1/4" |

| Part Length |

|---|

| 6" |

| Horizontal Stations |

|---|

| 16 |

| Vertical Stations |

|---|

| 8 |

| Index Time |

|---|

| 0.8 sec |

| Weight LBS |

|---|

| 16,500 |

| Machine Power |

|---|

| 60HP (Avg) |

| Typical Unit Size |

|---|

| DM2 40/90 CNC |

| DM2 55/120 CNC |

| DM2 55/200 CNC |

| Blank |

|---|

| 4" Cube |

| Round |

|---|

| 1 3/4" |

| Part Length |

|---|

| 8" |

| Horizontal Stations |

|---|

| 12 |

| Vertical Stations |

|---|

| 6 |

| Index Time |

|---|

| 1.2 sec. |

| Weight LBS |

|---|

| 18,500 |

| Typical Unit Size |

|---|

| DM2 40/90 CNC |

| DM2 55/120 CNC |

| DM2 55/200 CNC |

| Blank |

|---|

| 3" Cube |

| Round |

|---|

| 1 3/4" |

| Part Length |

|---|

| 8" |

| Horizontal Stations |

|---|

| 16 |

| Vertical Stations |

|---|

| 8 |

| Index Time |

|---|

| 1.0 sec. |

| Weight LBS |

|---|

| 20,000 |

| Typical Unit Size |

|---|

| DM2 40/90 CNC |

| DM2 55/120 CNC |

| DM2 55/200 CNC |

Have Questions? Reach Out.

Speed of service, cost savings, parts availability and state-of-the-art equipment set us apart from the competition.

How Our Servomats Have Helped Clients

Reduction in Part Cycle Times

A customer who replaced an old hydraulic-based CNC with a Servomat saw a reduction in their part cycle times of up to 30%.

Gain in Tool Life

Due to the accuracy of the DM2 CNC units and the increased rigidity of using ballscrews, Servomat customers have seen an up to 50% increase in tool lives compared to legacy hydraulic-based machines.

15-minute same stock part changeovers

Customers who switch to Servomat have been able to achieve 15-minute same stock part changeovers and one-hour different stock changeovers due to the combination of CNC units, quick-change HSK toolheads, quick-change collets and ease and flexibility of the Fanuc 30i control.

What Our Customers Say

“I believe in the team concept. We will do more and have a better product if we work together. RMW, from what I see, has that same vision.”

Matthew Bremiller, Engineering Supervisor

Dapco Industries

"Working with RMW says that I want to get things done the right way."

Steve Danielson, Manufacturing Engineer

Parker Hannifin

“Just like my business, RMW has the desire to solve problems quickly and effectively.”

Brian Thompson, Engineering Supervisor

Swagelok

"RMW excels at providing straightforward answers and accurate information."

Tom Kilpatrick, Senior Process Engineer

Alco

"RMW wants you and your company to succeed!”

John Riley, Process Engineer

Whitesell Precision Components